SHARING OUR EXPERTISE ON FACTORY NOISE AT THE CNESST 2019 FAIR

Last October, the Grand Rendez-Vous in Health and Safety 2019 was held at the Palais des congrès of Montréal. We presented some security products such as our Industrial protective clothing designed to withstand extreme temperatures as well as our custom-made Equipment protectors to ensure the safety of operators in a multitude of situations.

In addition, since there is a real concern for the health and safety of employees exposed to noise on a daily basis in the course of their duties, we have presented some sound insulation products. Noise intensity is often perceived as a problem that is difficult to manage in a manufacturing plant, machines being the main source, and the standards in this area being fairly strict in Canada, an employer must verify periodically the sound level in its factory to protect the health of its workers as well as to provide a working environment of quality.

When the noise level increases above the reference level of 90 decibels, the admissible exposure time must be reduced, or the necessary measures taken to reduce the noise. To calculate the maximum permissible exposure time, an equivalence coefficient of 3 decibels is used. The equivalence coefficient is the value by which the permissible sound level can increase when the exposure time is reduced, or vice versa, must decrease when the exposure time must be extended. Above the reference level, for each additional 3 decibels, the daily exposure time is halved, which is far from negligible.

Noise exposure limit for a reference level of 90 decibels |

|

| Equivalence coefficient of 3dB | Maximum permissible daily duration (hours) |

| Permissible level, dB | |

| 90 | 8 |

| 93 | 4 |

| 96 | 2 |

| 99 | 1 |

| 102 | 0,5 |

| 105 | 0,25 |

To remedy this "noise" problem, we manufacture acoustic insulating curtains and mattresses which considerably reduce the noise intensity and which allow temporary or permanent use by being able to adapt to more than one situation. Materials and manufacturing will vary depending on the type of equipment, the environment in which this noisy equipment is located, and the level of noise reduction required depending on the exposure length.

At the CNESST 2019 industrial fair, we exposed a box covered with a sound absorbing mattress in which was placed a radio emitting sound similar to that which can be found in a manufacturing plant, the aim being to prove the effectiveness of our product. Our tests were able to demonstrate its performance by reducing the strength of the sound emitted to almost 20%. Which is huge considering the equivalence coefficient of 3 decibels. On the other hand, our tests have also shown that, for the same mattress design, the louder the sound, the less effective the acoustic mattress, the percentage of noise reduction gradually decreasing with the intensity of the sound. This is where our expertise on the design of the mattress and the choice of materials comes in. A quality design will be reflected in the effectiveness of the product and the expected results.

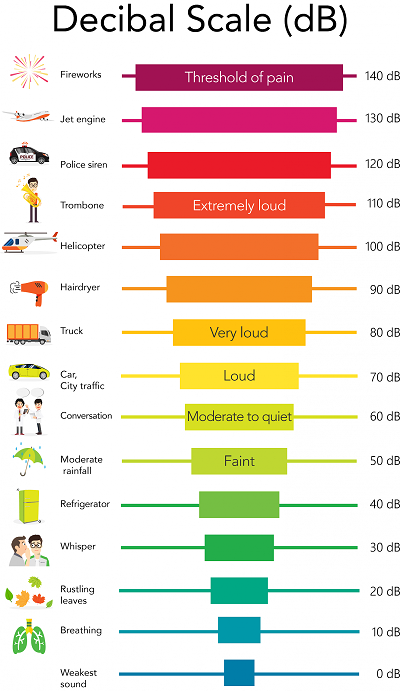

To get an idea of the number of decibels emitted in certain places in your work environment, the table below illustrates concrete examples of the number of decibels emitted in various everyday situations. Get ready to play, pay attention and listen. You will be surprised to note that the types of noise are very varied and that the risks related to workers' hearing health are very real. It remains only to identify and assess the sources of noise and then to take the necessary actions to limit them as much as possible. When simple earplugs are no longer enough, it becomes necessary to consult an expert: Industries 3R is there to advise you. Do not hesitate to contact us.

.