OUR NEWS IN EQUIPMENT PROTECTION

|

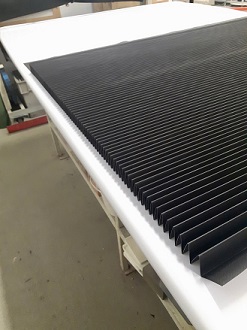

WELDED PROTECTORS: AN IRREPROACHABLE MANUFACTURING QUALITY For many years, Industries 3R has been designing and manufacturing custom equipment protectors that can be adapted to all types of machines: protectors for endless screws and cylinders, rail covers or lift covers. Sewing, as a method of assembling materials, has long been the ideal solution for the manufacture of this kind of product. Always on the lookout for new technologies, Industries 3R likes to stand out from the competition and does not hesitate to invest in high-performance equipment. In order to offer a superior quality product, Industries 3R is equipped with high frequency welding machines to assemble its equipment protectors. The process of welding fabrics requires expertise that we have acquired through research and testing necessary for its application. High frequency welding is mainly used on thermoformable fabrics such as our 3R513 composed of polyester and vinyl or on polyester / polyurethane fabrics as our 3R418. These fabrics are welded directly to the PVC reinforcements. Tests that look very promising are currently underway with fabrics composed of kevlar. Compared to sewing, this manufacturing process allows greater accuracy in the spacing between each reinforcement, thus improving the effectiveness of the protector. In addition, the weld gives complete impermeability to the product. This irreproachable quality of manufacture is very appreciated by the customers because it offers in addition to the product an incomparable estheticism. Evaluation and improvement of manufacturing processes have always been at the center of our company's concerns and that is what makes it so successful. RAIL COVERS WITH METAL DEFLECTORS Industries 3R now offers a new solution for equipment protection: rail covers with metal deflectors. This type of protector is ideal for applications where the environment is more aggressive: metal splinters and dust, projections or sparks due to welding, etc. We have developed this product in order to offer our customers a product that can meet their needs in these particular cases. Unlike traditional rail protectors made exclusively of specialized textiles and PVC reinforcements, we now offer a solution where the same product is covered with metal deflectors allowing extraordinary durability of the product by limiting the damage caused for example by metal splinters in a CNC machining center. Rail covers with metal deflectors are mainly used in horizontal applications. The development of new products has been in the niche of our business for a long time and remains at the center of our priorities, which contributes to the success of Industries 3R. . Rail protector with metal deflectors installed on a horizontal milling machine

Metal deflectors installed on a protector made with 3R418 |

Welded lift cover in yellow fabric 3R513

Interior with PVC reinforcement High-frequency welding: irreproachable quality

|

|

|

|