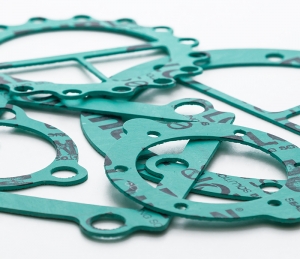

Durlon® 8500

Durlon®

Durlon® 8500 contains aramid and inorganic fibers bonded with high-grade nitrile (NBR) rubber. Durlon® 8500 exhibits good compressibility and recovery, excellent sealability, flexibility and cutting characteristics.

Downloads

Applications

- Oils

- Water

- Steam

- Refrigerants

- Dilute acids and alkalis

- Industries: Pulp and paper, Food and beverage, Pharmaceutical, Hydrocarbon, Chemical

Specifications

Technical Data

| Color | Green |

|---|---|

| Fiber | Aramid-inorganic |

| Binder | NBR |

| Temperature | Minimum: -73°C (-100°F), Continuous: 287°C (548°F), Short term: 371°C (700°F) |

| Pressure | 103bar (1500psi) |

| Density | 17g/cc (106lbs/ft3) |

| Compressibility | 8 - 16% |

| Recovery % | 50% |

| Creep Relaxation | 20% |

| Tensile strenght | 13.8MPa (2000psi) |

| Nitrogen sealibility (ASTM 2378) | 0.03cc/min |

| Volume Resistivity (ASTM D257) | 4.2 x 1013ohm-cm |

| Dielectric breakdown (ASTM D149) | 11.7kV/mm |

| Gasket factors m | 1/16": 2.7, 1/8": 4.2 |

| Gasket factors y | 1/16": 2359psi, 1/8": 2931psi |

| Gasket factors Gb | 1/16": 650psi, 1/8": 400psi |

| Gasket factors a | 1/16": 0.33, 1/8" 0.35 |

| Gasket factors Gs | 1/16": 200psi, 1/8": 20psi |

N.B. The information presented may differ from practice. We recommend conducting tests according to the conditions of use. We accept no responsibility for results obtained by the application of this information or the safety and suitability of our products. The data is subject to certain variations without notice.