3R872

Compressed sheets

Compressed sheet gasket material produced from carbon fibers and graphite, bonded with nitrile rubber (NBR). It is a premium grade, multi-service gasket sheet, designed to handle extreme pressure and temperatures and is easily clean cut. This versatile sheet minimizes gasketing sheet inventory.

Downloads

Applications

- Mild organic and inorganic acids

- Diluted alkali

- Water

- Brine

- Saturated steam

- Industrial gases

- Animal, synthetic and vegetable oils

- Petroleum and derivatives

- Aliphatic solvents

- Neutral solutions

- Refrigerants

- Air

Specifications

Technical Data

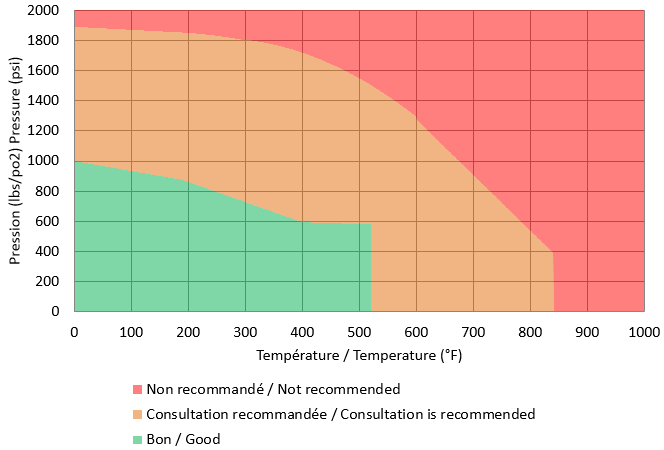

| Temperature | Continuous: 270°C (515°F), Short term: 450°C (840°F) |

|---|---|

| Pressure | Continuous: 1000 psi (70 bar), Short term: 1900 psi (130 bar) |

| Color | Black |

| Thickness | 1/64" to 1/8" |

| Sheet Sizes | 59" x 63" |

| Density | 106 lb/ft³ (1.7 gg/cc) |

| Compressibility (ASTM F36 J) | 5-15% |

| Recovery (ASTM F36 J) | 50% min. |

| Tensile Strength Across Grain (ASTM F152) | 2175 psi (15 N/mm²) |

| Ignition Loss (ASTM F495) | 50% max. |

| Creep Relaxation (ASTM F38) | 22% |

| Torque retention (DIN 52913) | 35 N/mm² |

| Sealability at 1000 psi (ASTM F37) | 0.2 ml/h |

N.B. The information presented may differ from practice. We recommend conducting tests according to the conditions of use. We accept no responsibility for results obtained by the application of this information or the safety and suitability of our products. The data is subject to certain variations without notice.